We’re finally getting back to our Brother KH-881 punch card knitting machine project (check out our previous knitting machine post)… and it’s time to make some punch cards! The KH-881 reads 24-stitch repeat punch cards, and uses the punched holes to determine where stitches are slipped, tucked, or knit in a differerent color, depending on the settings on the machine.

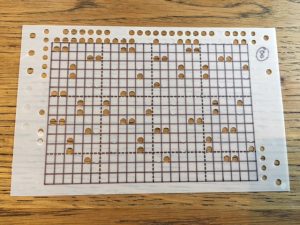

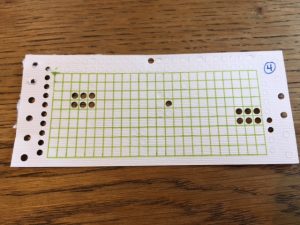

Some punch cards come standard with the machine, like the one on the left in the photo below. You can also hand-punch custom cards, like the one shown on the right:

It’s not difficult to make interesting custom designs by hand-punching cards. Here are some test patterns that I made using a special punch card tool, and two-color test swatches for each pattern:

Punching Faster

So, that’s nice and everything, but it turns out that punching cards is a PAIN. I thought it would be kind of fun, but after about a quarter of a punch card it is no longer amusing; there is a lot of squinting my eyes and lining up the punch and hunching over the card. And errors are a pain to fix; you have to tape the tiny holes back in if you punch things by mistake! In addition, I really want to be able to “fail faster;” if one trial of a punch card design isn’t quite right, I want to be able to modify it and try the new version again relatively quickly. Repunching an entire card is a slow and irritating way to do this iteration.

So, as if an antique knitting machine wasn’t enough of a craft money hole, I decided to get a Silhouette Cameo 3 cutting machine. As you can see from the marketing image below, the Cameo is a hobbyist-grade craft cutter that people use for scrapbooking and other artsy paper/sticker/vinyl projects. My goal is to use this machine to create knitting-machine-readable punch cards.

First Iterations on the Cameo

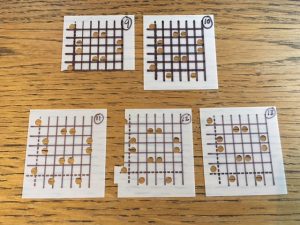

People so often show just their finished designs or products, but the story of iteration and failure behind every project is perhaps even more useful. So I took pictures as I learned to use the Cameo to make punch cards. Here’s the first thing (well, the first successful thing) I made with the Cameo:

The knitting machine punch cards are made of some kind of flexible plastic or laminated material. I went to the Michael’s big box craft store and got a handful of different types of paper to see what it would work. All of them were awful, including this crinkly one:

The only other type which came close to working was the original cardstock I had tried. But even that material only sometimes let me cut out the holes the whole way, even after adjustments to the cutter setting. In addition, the cardstock stuck to the cutting mat and was obviously not durable enough for the knitting machine:

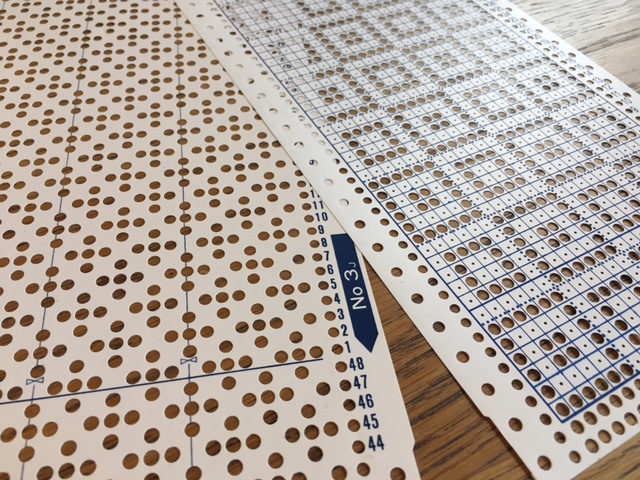

Dura-Lar Iterations

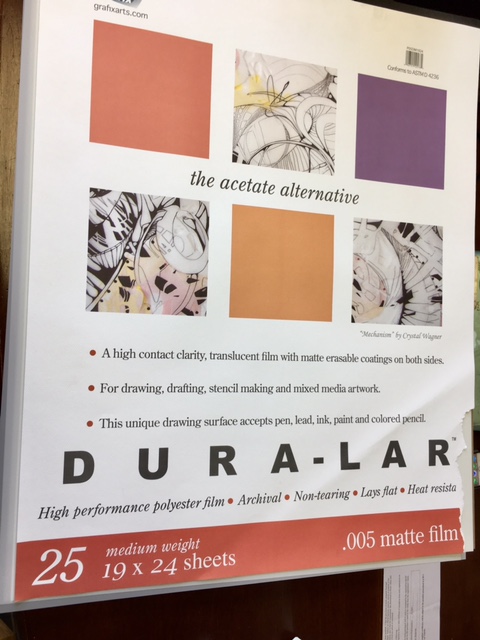

At my local craft store an actual live person recommended that I try sheets of Dura-Lar. It turned out to be perfect, so here is a picture of it in case you want to order your own. (I think this product on Amazon is the same.)

The Dura-Lar material is strong and flexible but doesn’t damage easily; it’s really sturdy. The holes cut perfectly into this material, but the pen refused to draw on it half the time, and was smudgy:

Replacing the Cameo pen with an Ultra-Fine Sharpie did the trick, but with this new pen, the drawing and cutting tools didn’t seem to be aligned properly:

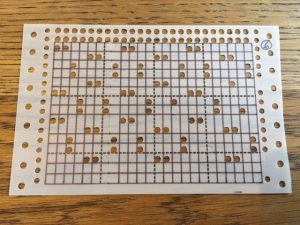

The heart of the problem was that the Dura-Lar could only be drawn on with Sharpie pens, but those pens were not exactly the correct diameter for the Cameo pen holder. Luckily, the knitting machine doesn’t give a crap about the printed lines, and only cares about the holes. So even though our next trial still had messed-up lines, we could use it to knit a pattern swatch with the KH-881; it worked!

Playing with cutting settings and alignment to try to get things to match up only made things worse:

At this point we realized we could do our tests with much smaller pieces, and save material. We tried using tape to build up the pen case width, and we tried using a custom pen holder. After many adjustments we almost got things to line up correctly.

Stay Tuned…

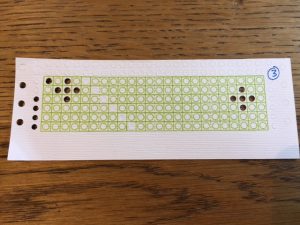

Although we did almost get things to work, the alignment process was really fiddly and sort of random. Worse, it wasn’t clear that the process was even going to be repeatable for future designs. Time for a break, and to wash all the dots off our cutting mat:

In our next post, we’ll solve our problem with (what else) some 3D printing…

——————

As an Amazon Associate we earn from qualifying purchases, so if you’ve got something you need to pick up anyway, going to Amazon through this link will help us keep Hacktastic running. Thanks! :)

I’m so excited to see this post! I went through some very similar iterations with DuraLar, trying to make 40 stitch punch cards for a Passap Jac40. I had real trouble getting the Cameo (I think mine is an earlier model) to cut through the DuraLar, and the little cut holes would pop off the mat and wedge themselves under the blade.

I used a sharpie fine liner for the drawing which barely fit the pen holder. Staedtler Lumocolour permanent pens are very skinny and work on regular punch cards so might be good on duralar too! Ditto with Pilot DVD markers.

I got so frustrated with the whole thing that I sold the JAC40, and I punch cards by hand for my Singer machine. I think I’ll re visit the Silhouette after reading these posts, thanks again for showing your process!